Hello, kinda new to the forum, usually on sksboards.com, but I own a SP-01, CZ-85B and a CZ-52, and I would like to share some info on an easy trigger job, enjoy!

This is my first detailed how to, so if anything is missing, confusing, etc let me know. Also this is do at your own risk, and remember to go slow and take off little bit at a time. Its much easier to remove material than to add it. I recommend reading thru the whole thing before attempting. While taking the pistol apart, it is a very good idea to take note of the postion of the parts and how they work together.

Also note CZ triggers usually need to break in (around 500 rounds) and the trigger will improve during break in, if this is not enough for you, then this may be of help to you.

This was done useing a CZ-75B SP-01, models with a decocker will be different than this one with a manual safety. I plan on doing this to a decocker model, but I don't have one...yet.

The tools I used are:

picks (like dental picks)

Punch

phillips screw driver

sand paper (400 grit I found works well)

and a paded vise

First off you need to unload and field strip your pistol

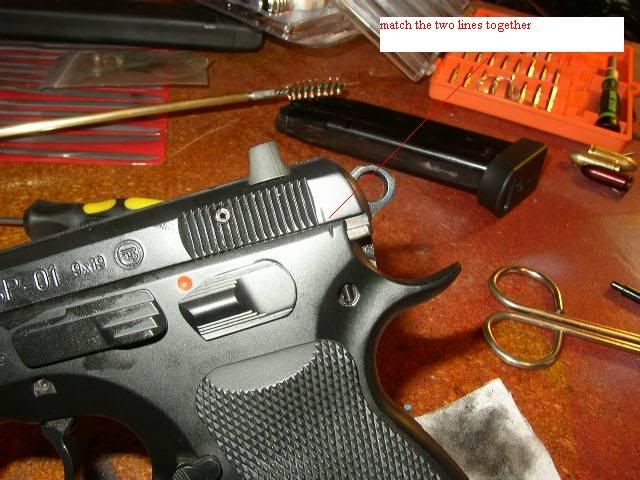

Remove the magazine, then align the two lines on the rear of the slide:

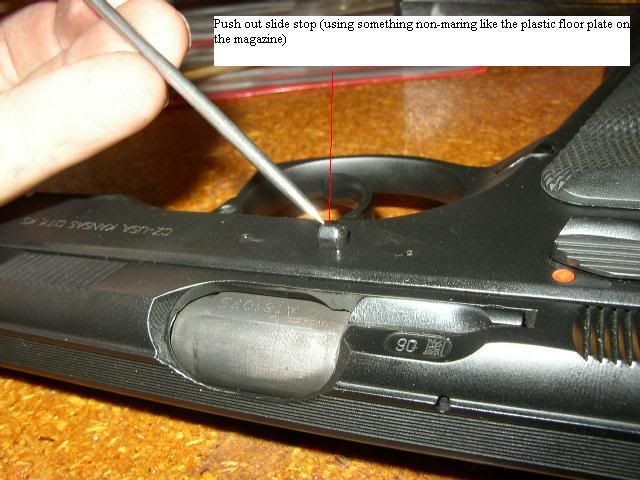

Push out the slide stop

then pull it out

The slide will now pull off towards the front, removing the barrel and spring is not required for a trigger job

-----------------------------------------------------------------------------

next remove the grips using a phillips screw driver

remove the mainspring plug pin (under pressure, push the plug against a table or simlar surface while doing this)

then carfully take out the magazine break like so lifting up and pulling forward:

Then release the mainspring plug

Pull out the plug and mainspring

----------------------------------------------------------------------------

Next lift up on the sear spring

while lifting up the spring pull out the safety (helps if its on safe to give more to grab onto) The CZ-85B you have to pull out both sides of the safety

lift out the trigger assembly

Remove the sear pin

taken apart, be careful of the two small springs in it (sear spring and firing pin block lever spring)

------------------------------------------------------------------

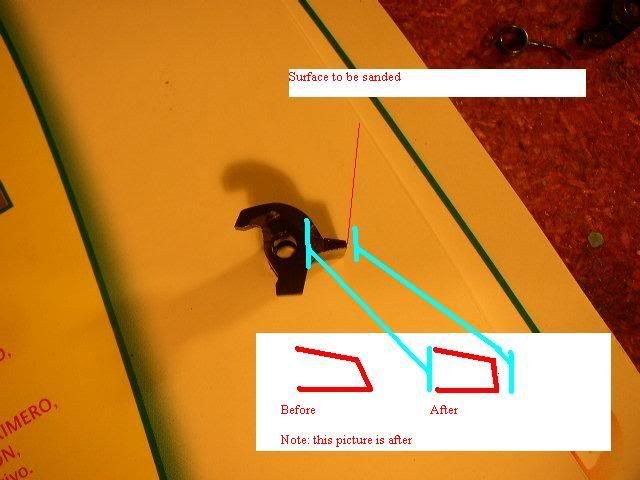

Next sanding on the sear. I use 400 grit paper and found it to be effective, while sanding I found putting the paper on a flat surface and carfully taking the sear across it the best way do sand it down, though other ways such as using a vise may also work. Also do not round any corners off!

The part to sand, this is after and it gives good trigger pull and weight. Do a little bit at a time to be safe, an note hammer engagement. When the trigger is pulled in single action, if the hammer moves back before releasing this is positive engagement (safest), if it doesn't move its neutral, and if it moves forward, negative (most unsafe). My goal is to have minimal postive engagement, though neutral may be desirable for a target oriented pistol)

Now reassembly of the trigger assembly (basically reverse order)

Leave firing pin safety lever spring like this for reassembly...

Then while carfully pushing lever towards its side move spring to its correct position

Reassembled

--------------------------------------------------------------------------------

Next is to get the hammer out

Push the safety detent plunger inward

and remove

next is to remove hammer pin retaining peg

Push up on it from here

then pull out from the top using tweezers

Push out the hammer pin

pull the hammer assembly out of the top

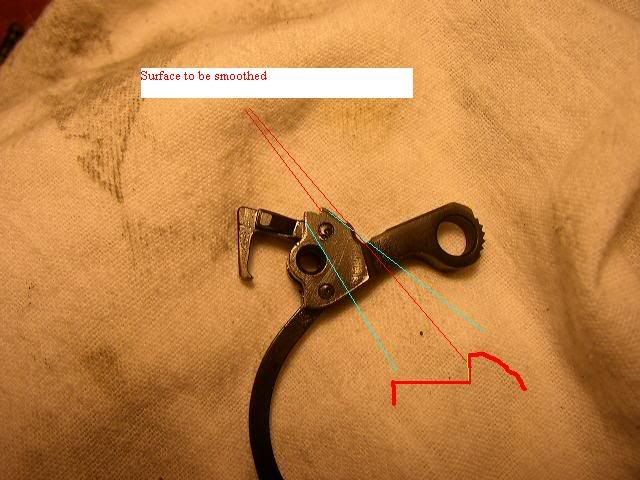

Shows the surfaces to be smoothed, also don't round any edges. I would recommend keeping the angles the same here too, can be angled backwards but I recommend against it, as it may cause negative engagement

----------------------------------------------------------------------------

Reassembly is just reversed, but with a few helpful tips

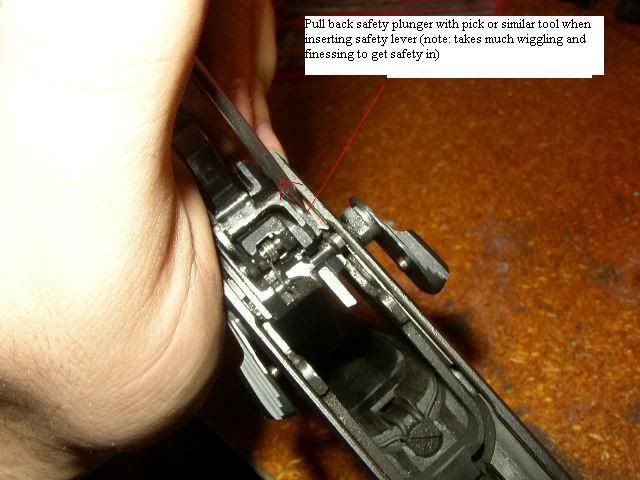

Lift this spring when putting safety back in

then push back the safety detent plunger back far as you can, while pushing safety back in.

Then reversed order on the main spring and grips and slide.

The mainspring also may be changed too as well to help with trigger pull, especially with double action. I used a Cz-52 spring since I have extras and found them to be reliable, you can get the same effect as cutting coils off, but that is un reversable and you may make it too light, you can get lighter springs here:

www.gunsprings.com/SemiAuto/EAANF.html Then as usual function test the pistol and safety.

I hope this helps make your CZ trigger much better. I have tried my best to make it clear and concise, but let me know if you run into any snags while trying this.

-Sterling