Forgive my ignorance but what is

"bad case webbing"

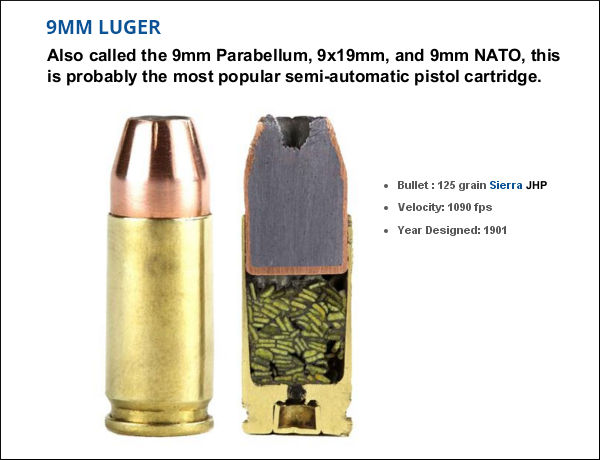

If you'll look at the bisected case on the right:

I have seen the case web described two different ways:

- In the picture above, from one side of the case to the other, the thick section of brass that the flash-hole passes through. OR...

- In the picture above, just above the thick brass section the flash-hole passes through, it's the area where the case walls are very thick.

I suspect the first one is correct. However, this normally comes into play in discussion of incipient casehead separation, where the brass just above the web gets stretched thin during firing and resizing, and eventually blows out, so that whole area tends to get covered in the discussion. If someone can be more precise on the definition of the web, please add. I'd love to be sure.

In the case of CZ saying it's bad case webbing, the brass in that area is thicker because no chamber fully supports that area of the case, so it needs a little more strength. CZ is saying that area was not as strong as it should have been. Brass cases start out as brass disks, then they get pushed through a die and turned into a brass cup, then the cups get pushed through die after die after die to stretch and shape them into what they are. CZ is saying that during that process, some or all of the web got stretched too thin and couldn't contain the pressure it needed to contain.