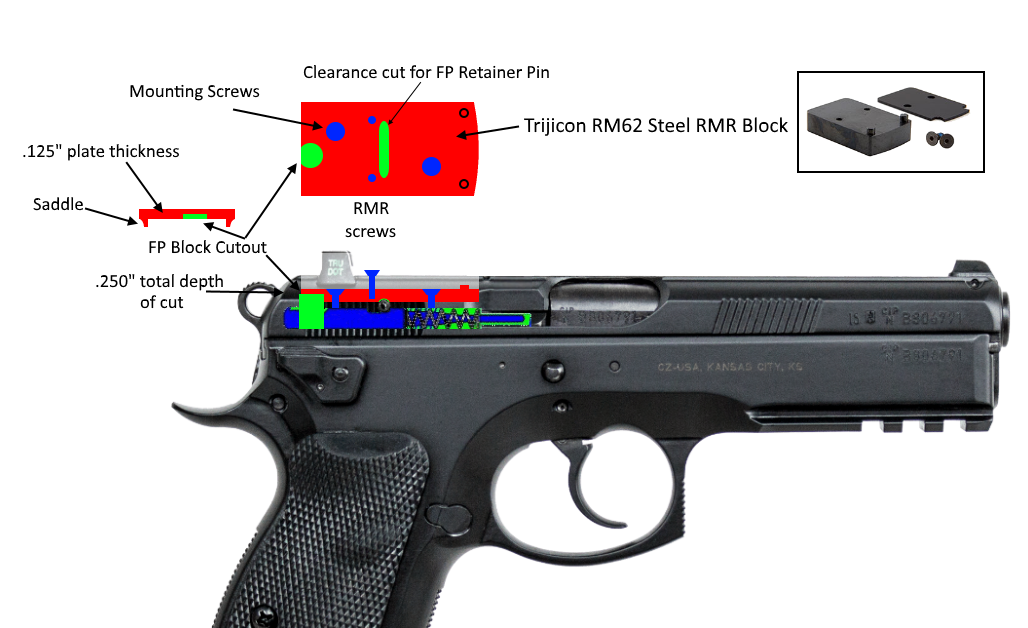

I want to setup my SP-01 Tactical with the new Trijicon SRO for competition but before I send it off to an established company, I want to see if anyone will accept a custom job. I haven't found a place that install an RMR adapter plate much lower than the top of the slide and the CZC RDS plate leave some pretty large gaps. I get that they're trying to avoid the FP retaining pin and FP Block recess but I'm thinking this can work if I start with a steel plate. It should be strong enough to support the FP block and retainer since the forces aren't really that great, and the sheer forces are contained by the pocket walls, while the 1911 adapter style saddle prevents the pin from sliding out. I figure offsetting the mounting screws will better distribute the forces and with the deeper cut, it can be mounted farther back to clear the extractor pin hole. With the top of the plate surface .125" below the top of the slide, the optic body will be supported by the pocket instead of relying on the two round lugs.

Before you ask if .125" is really worth it, I'm one of those people who hates to leave anything on the table. Having the window low means my peripheral vision can pickup the top of the slide or front sight sooner as I press out from the draw and guide the dot to my eyes. I have no problem chasing grams, or thousandths of an inch. Even if the performance benefit is minimal, just knowing it isn't as close to perfect as it can be will haunt me to my grave. As an added bonus, at that depth I can run a .315-.330" tall front sight. By milling a channel at the rear of the optic body and color filling it white, I can "dot the i" with the fiber dot and get a rough iron sight picture on the off chance my optic dies mid stage.

I work in the racing industry and have access to a 2-axis CNC mill at our shop. I've been playing with it, doing minor projects after hours but I'm no machinist. I even have the CNC program written out and ready to test in delrin, but steel is a completely different thing and I know that there's a lot I don't know. Since I don't have a spare 75 slide to test on, I'd rather pay a professional since spare slides aren't exactly cheap or plentiful. So does anyone know of any shops that might be willing to take on a project like this?