TLDR: I'm clearly insane

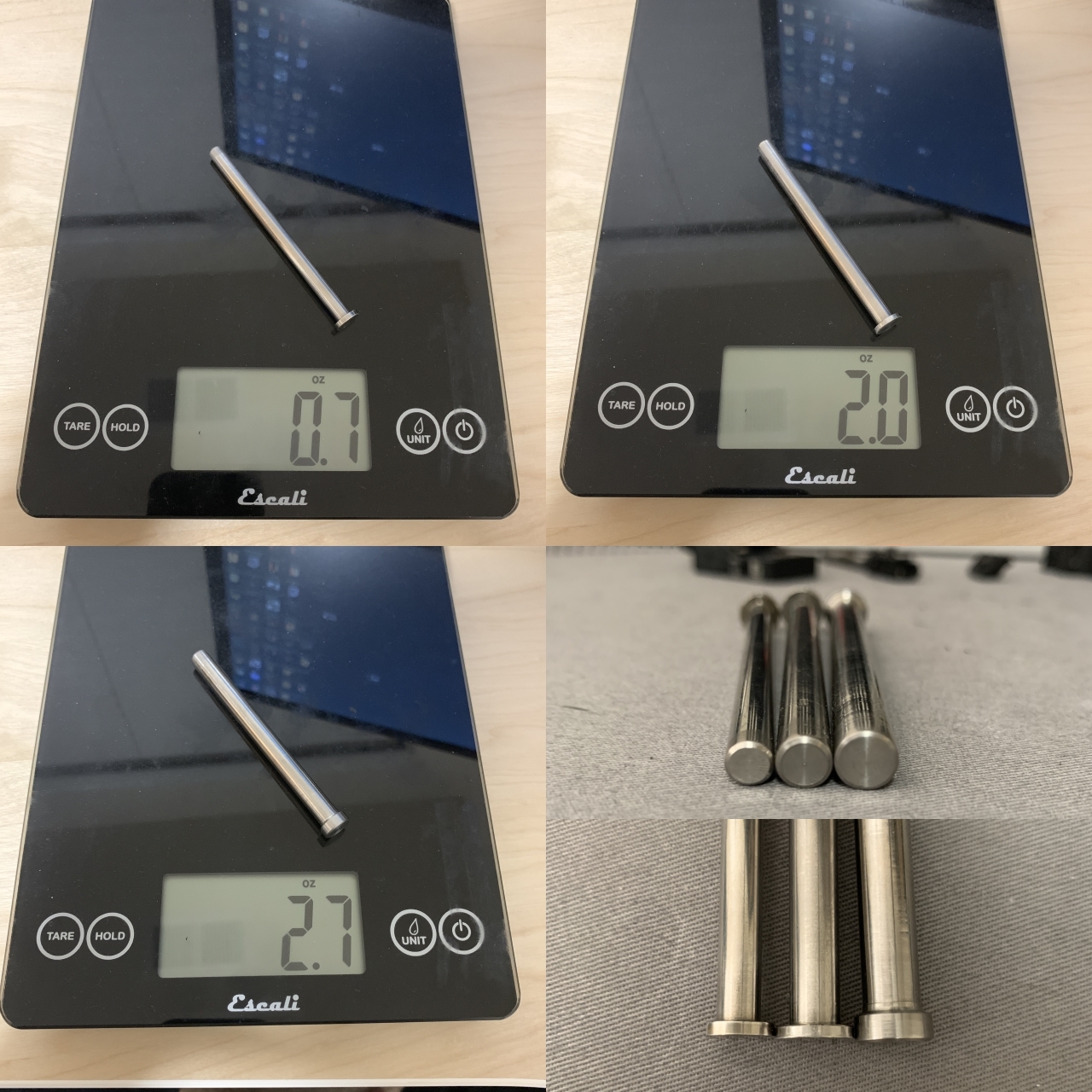

So it's common knowledge that the P-10C&F guide rods are nearly identical to Gen3 Glock guide rods except in length. Since I wanted to optimize my recoil springs to my competition loads, I bought a CGW stainless guide rod and some flat-wire ISMI G17 springs. The CGW rod weighs 0.7oz, the same as the OEM rod, but is uncaptured for easy spring changes. Since I'd had good luck with 13# springs in my G34, I figured they'd be fine in the P-10F. However, the P-10F's heavier slide was allowing the gun to return high. I popped in a 15# spring to he same effect. Even with a 17# spring the gun was flippy and returning high. With the factory spring back in, the muzzle was dipping low. It didn't make sense that the lighter springs were acting like they were heavier than OEM.

Annoyed, I decided to throw more money at the problem. A while back I switched my Glocks over to round wire springs and larger diameter guide rods. Round wire springs tend to cycle smoother and the larger guide rods adds more weight under the muzzle. So I grabbed a Gen3 Extended G34 Tungsten Heavy guide rod from Jentra. The Heavy version is thicker than standard at .275" and I wanted the extended version so I could cut the length down flush with the slide. After facing the tip on a lathe, it ended up weighing 2.0oz, 1.3oz more than OEM. I finished it off with a set of Sprinco G17 round-wire springs. Surely all that extra weight would help.

Confident, I hit the range, popped in a 15# spring and...the dot was still returning just above the A-zone at 7 yards. If anything, the muzzle flip was worse. The 17# spring didn't help either.

Back home, I tore into the gun again looking for the problem. At that point, I realized I was an idiot. I had completely forgotten to check the slide's travel with the new springs. As it turns out, the coils were binding and preventing the last 2mm of slide travel. The slide slamming into the frame early wasn't giving the recoil spring enough time to slow the slide's rearward velocity. I had to cut about 2.5 coils off the springs to restore the lost travel. But shortening the length reduces the preload while simultaneously increasing the spring's rate. At that point I decided it would be easier to just use G19 length springs. Browsing the web for springs, I saw that GlockStore had released a 2.8oz "Pure Tungsten" guide rod for Gen4/5 Glock17s.

Now at this point, a reasonable person would just be happy with the 2oz guide rod and call it a day. But I'm not that person. Knowing that the Glock guys could enjoy an extra 0.8oz would keep me up at night. At least that's how I justified spending $120 on a part that I wasn't confident would even fit my gun.

I didn't know the diameter of the rod, nor did the customer service rep, just that they were larger and used special springs, but I figured I was in for a penny in for a pound at this point. I ordered the Gen5 G17 rod and also bought 13#, 15#, and 17# G19 recoil springs from Sprinco. The rod arrived yesterday. Right off the bat it's not as nice as the CGW or Jentra rod. The front wasn't cut very evenly, and the rod surface feels wavy, like it was cut with worn tooling or flexing a lot in the lathe. Not that it matters because it also doesn't fit. The guide rod hole in the P-10F's slide is .300". The Glockstore Pure Tungsten Gen4/5 Rod is .310" and bulges slightly to .315" about 1/2" back from the muzzle end, before tapering back to .313" at the rear. The diameter at the back is .503" compared to .415" for the Gen3 and P-10F, and won't seat in the frame. Fortunately I have access to a machine shop. Today I turned the back portion down to .415", and also took 0.040" off the front face. This would give me an extra coil's width of travel. I calculated that it wouldn't bind with the G19 springs, but figured I could use the insurance. I also took .028" off the tip to clean it up and correct the length. I left the bulge since it begins inside the slide's guide rod tunnel and won't effect the spring or slide movement. After removing the material, the rod weighs 2.7oz.

I was going to just turn down the guide rod to .285'', but I calculated it would bring the weight down to 2.2oz. Not really worth the money and time for a 0.2oz improvement over what I already had. Then I thought, why not just make the slide hole larger? I'll need to get it re-nitrided, but that gives me an excuse to get some additional front serrations and lightening cuts. Unfortunately I didn't have the slide with me, so tomorrow, I'm going to ream the hole out to 8.5mm or .3346". Hopefully I can figure out a way to fixture the slide in the mill and not burn up any tooling on the hard nitride finish. Wish me luck.

Here's the CGW, Jentra, and GlockStore (after cutting) guide rods for reference.