Wobbly, I appreciate the opportunity share points I have learned over the past year from all of you here on this forum. If any newbie would like to reach out to me, please PM me even though questions are encouraged to all members. Heck it was the only way I learned!

Reloading Precautions1. A Clean and neat work space is critical for consistent cartridge reloading. Clutter causes confusion & distraction. Clean and organize your space before each session.

2. Note Taking - Keep a well documented notebook, paper or electronic, on all your test loads. This data is critical to produce safe accurate loads using different powder and bullet combinations. If you keep a paper manual, attach the test targets to the back of your load data page. If you keep electronic data, take a photo of your test targets and insert the photo into your test files.

3. Stay Alert and avoid distractions - no interruptions. If you are forced to stop in the reloading process, make sure you have a set procedure in place to re-start where you left off. Missing a step like not seating a primer can be messy when you drop powder but dropping a double load of powder after an interruption can be catastrophic!

4. Procedures - Stick to them! It may take practice but you will eventually find you perfect procedures to follow each and every time you sit at the bench. Just as you need muscle memory when practicing proper shoot techniques, you need the same muscle memory during reloading. The same pull pressure on your press arm for each stage will make for smooth reloading and consistent rounds. Remember Practice Makes Perfect!

5. Check press before starting. Check all connections ? Set screws, nuts, links, and dies - to make sure they are secured properly. A loose link on the powder drop can result in a missed powder load which can lead to squibs. Inspect your equipment before each session!

6. Lighting - Good lighting is critical to visually inspect cases prior to starting the reloading session and good lighting is also critical to visually inspect powder levels after you drop powder into the case. Whether you are on a single stage or a progressive press a visual inspection of powder level in your case is prudent.

7. Case Sorting ? Sorting by headstamp is not a requirement. Many reloaders prefer the consistency of one headstamp. What to look for no matter if you sort by headstamp or not:

a. Damaged Cases ? specifically look for worn, split cases

b. Cases with Pressure signs ? Flattened, missing, or extended primers or extractor grove recess

c. Many times fired cases ? Typically the headstamp is worn or hard to read

d. Crimped Primer Pockets ? typically military brass

e. Steel Case ? Get Rid Of Them

f. 9mm Reloaders, be aware of .380 cases ? they WILL reload in your press!

g. .45ACP Reloaders - Primer pockets in .45acp are two different sizes. Mainly .45acp cases are Large Pistol Primers but approximately 5% of the primers are Small Pistol Primers. Also, be aware of several case head stamps have very tight primer pockets. S&B, HRTRS, and some other European case manufacturers are notorious for tight primer pockets.

8. Work Flow ? Single Stage and Progressive

a. De-prime/Re-size

- Single Stage - Working in batches on a single stage will create consistent loads. If performed in one sitting, hundreds of cases could be prepped during this step. During this process, there are attachments for some presses that will also allow you to insert and seat the primer in this stage also.

- Single Stage or Progressive - Be aware of proper adjustment depth of your sizing die. Make sure the die is adjusted down to the case head. Read the die installation instructions provided with your dies & press.

b. Case Flair - Whether you are reloading for an automatic or a revolver, this step is required in order for the bullet to seat in the case properly. Be carefully not to overly flair the case since it may not feed into the next die. Conversely, too little case flair will cause the bullet to be tight during the seating stage and possibly damage the bullet. In the case of lead bullets, it could shave lead off the bullets and create ?eyelashes?.

c. Priming - Typical presses seat primers on the down stroke. Whether you hand prime or load with a primer feeder on your press, be aware of primers that get flipped in the process. Stay consistent and make sure the primer is set flush with your case. A primer that is raised can cause havoc at the range. Also, be aware of several case head stamps that have very tight primer pockets. S&B, HRTRS, and some other European case manufacturers are notorious for tight primer pockets.

d. Powder Charge

- Single Stage or Progressive

1. Always double check your load data! Set your scale to the weight you plan to use as your load. Adjust your powder measure accordingly, drop test loads of powder in a clean case. Once your powder measure is dropping the correct load weight that you have measured on your scale, it is prudent to drop 10 loads of powder on that weight on your scale. Adjust the weight 10 fold on your scale to see if there is a deviation in the overall weight. If the weight is off, adjust accordingly on your scale and drop 10 more until consistent. You are now ready to drop powder into your cases ? single stage or progressive.

- Single Stage ?

1. What is needed for this stage

a. Powder Measure

b. Scale (Balance Beam Preferred)

c. Case Reloading Tray

d. Funnel

e. Flashlight or bright desk lamp

2. Most case reloading trays hold 50 cases at a time. Load 50 cases on your tray. Make sure your tray is stable and does not slide as you drop your powder. Once you have carefully filled each case, take a flashlight and examine each case for powder level. Look for cases with no powder or double charged cases. Once examined and each case approved you are now ready to seat your bullets.

- Progressive

1. Proper lighting on a progressive is very important to ensure visual inspection after each powder drop. Some manufacturers offer Powder Cop dies for progressive presses. This is an individual choice but there are other dies options of higher value in the reloading process.

e. Bullet Seating

- Single Stage or Progressive - Calipers are a requirement for this stage. Understanding your OAL (Overall Length) for your firearm is very important for this stage. Please read the sticky regarding your plunk test here on the CZ forum. Once you know your OAL for your load, double check the load manual to make sure your OAL falls between the load manual safe points. To set up the depth on your bullet seating die, use unprimed cases that have been sized. Adjust the seating die and insert a bullet into the un-primed case. Pull the arm on your die and seat your bullet. Remove the test round from the press and check OAL with your calipers. Repeat the above process until the proper OAL is achieved. NOTE ? in place of several un-primed cases, you could use a kinetic hammer and remove the test bullet from the case as to not use many cases in this OAL testing process.

1. Single Stage - Once you have identified the correct bullet seating depth ? OAL, put one bullet on each expanded case on your reloading tray. One at a time, place each case/bullet on your press and seat the bullet.

f. Crimp

- Single Stage or Progressive - Some seating dies incorporate crimp. This does save one step in the reloading process but it also is much more difficult to adjust. It is highly recommended to crimp in a separate step. Be aware that automatics and revolvers require different crimps. Automatic requires a taper crimp basically to remove the bell in the case from the expansion die. Revolvers on the other hand require a roll crimp to hold the bullet in place so the bullet does not move during recoil. Many revolver bullets have a crimp grove to roll the crimp into. Typically, revolvers are forgiving on the amount of crimp and a taper crimp could be efficient for many standard target loads. +p loads and magnum loads should have a roll crimp incorporated in this stage. Once the cartridge is complete, it would advisable to do a drop test in a case gauge but the best test would be in the barrel removed from your pistol.

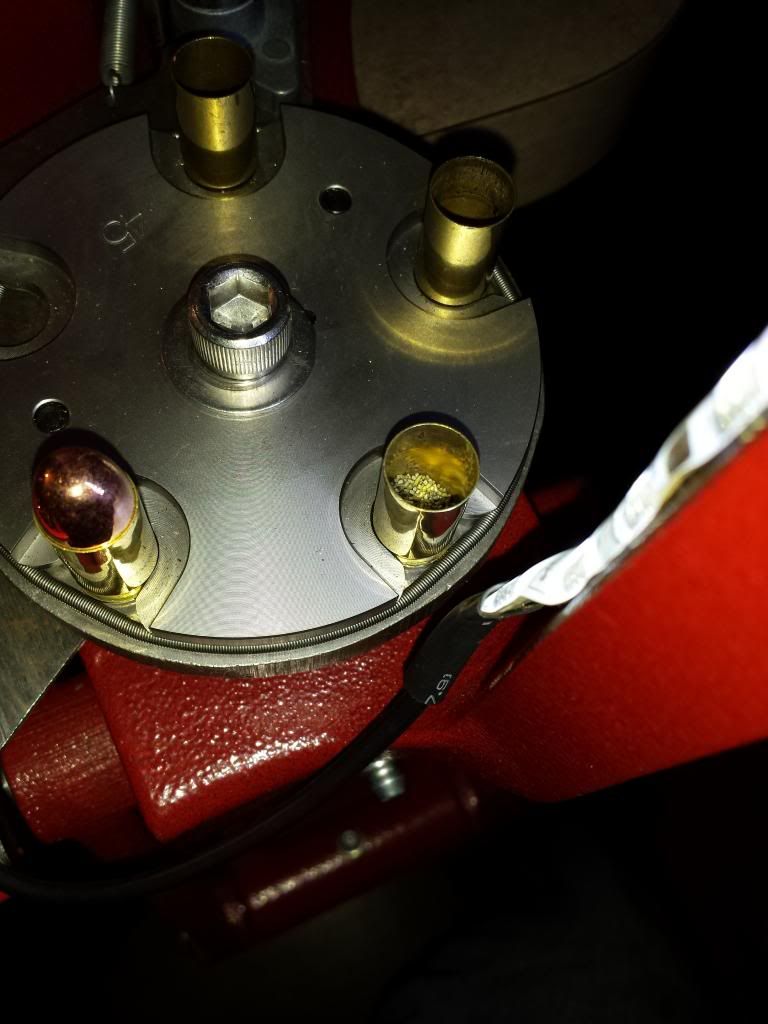

Progressive Press with 5 Stages

g. Proper Cartridge Box Identification

- After you have completed your reloading, it is highly recommended to keep your cartridge boxes well marked. Here is the recommended data to have on the outside of each box

1. Caliber

2. Date Loaded

3. Powder

4. Powder Charge Weight

5. Bullet Manufacturer

6. Bullet Type & Weight

7. OAL