PART 3 SEARTonight we are going to install the new sear and set the safety.

We have a lot to talk about and I am sure there will be some discussion with what I have found.

A couple of us have noticed that Caniks have some variation in builds, whether it is the feel of the trigger, the width of the frame, or in tonights case the dimensions of the sear cage.

I started the simple but, meticulous task of installing the new sear, Firing ping lifter assembly, and associated springs only to find that I had an interference fit.

Meaning parts were rubbing against each other and HARD, enough that the sear or the lifter would not move.

So I Emailed Schmeky and sent pictures of the issues.

He confirmed that Canik makes rolling changes, and that as he put it "Hard to hit a moving target" and that he will be making adjustments to the next batch.

His advice to make it work is just as I thought trim the side of the sear or sear body where they are making contact, and that this will not cause any issues.

It reminds me of a certain Italian motorcycle manufacturer, that has always made rolling changes in the middle of the year, and if they find some old parts they throw those in also.

So I am going to say it now, tonights mods are not for the faint of heart.

It can be scary resizing small parts, but not as hard as you think.

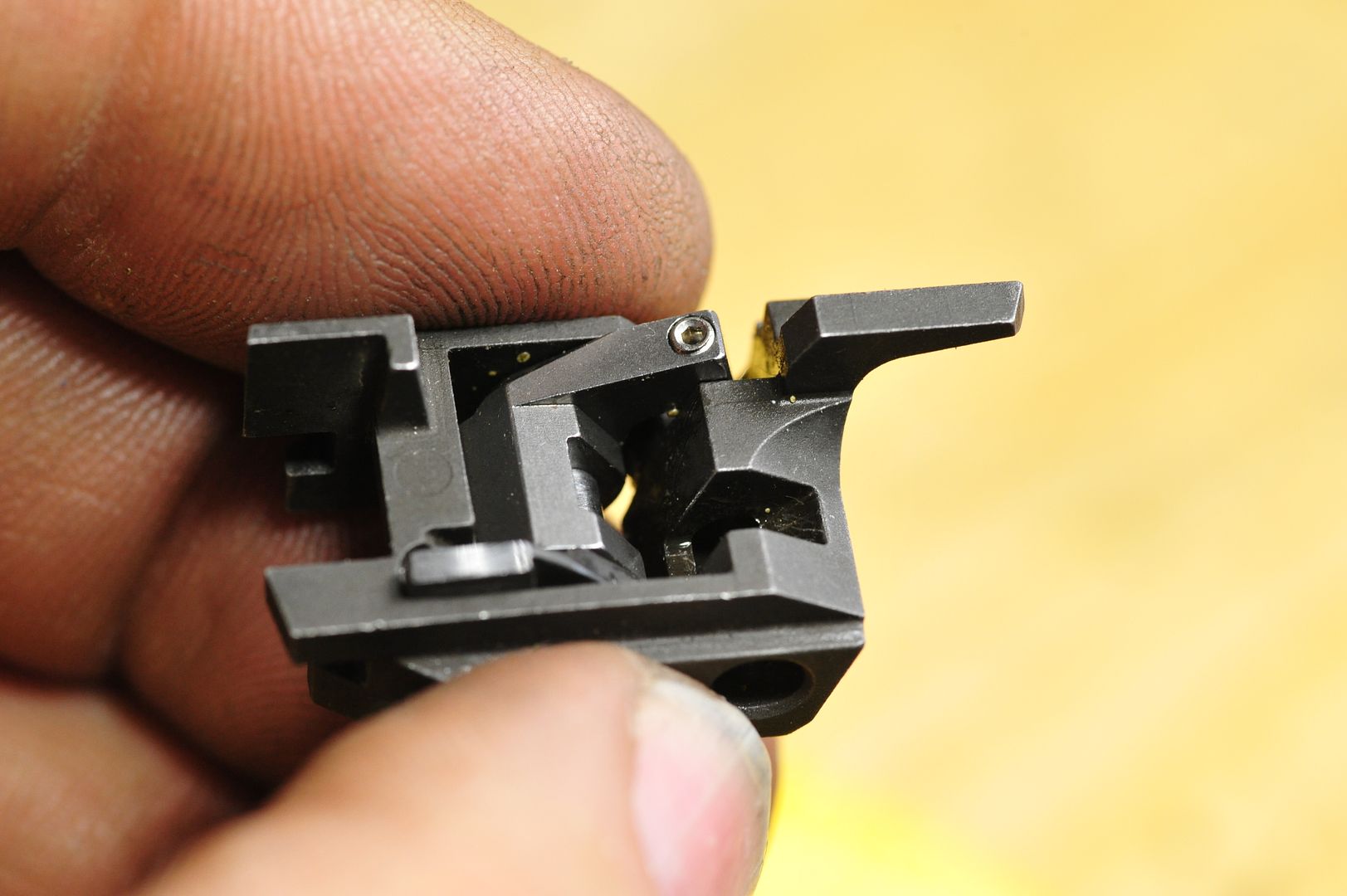

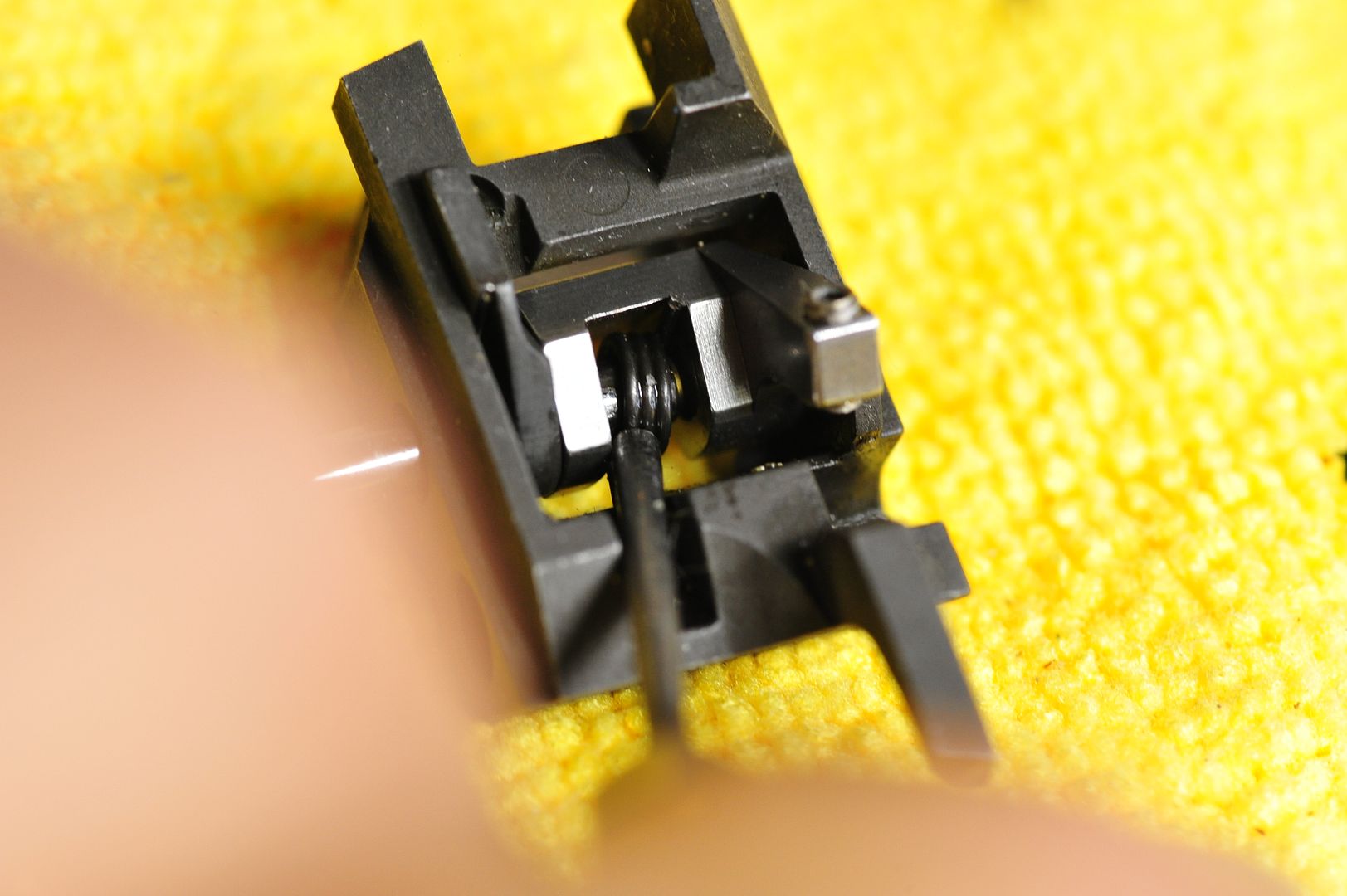

In the following picture you can see the safety arm hitting the inside edge of the sear cage pulling the sear to the left.

In this view of the bottom you can see the sear pulled to the left and binding against the left wall.

I am getting ahead of myself, in part 2 we talked about removing the sear and kind of stopped there.

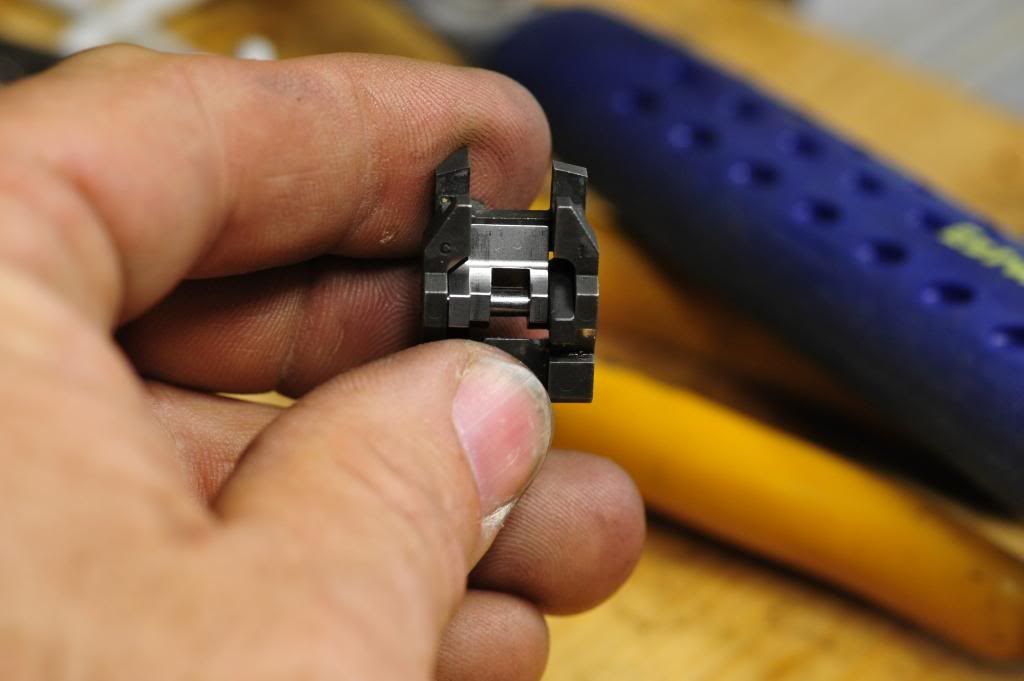

Disassembling the sear cage is pretty simple but you need to use caution if you are reusing the parts.

You need to place a finger on the top and bottom of the sear cage and push the pin out sideways.

The fingers will keep the loose parts from flying out.

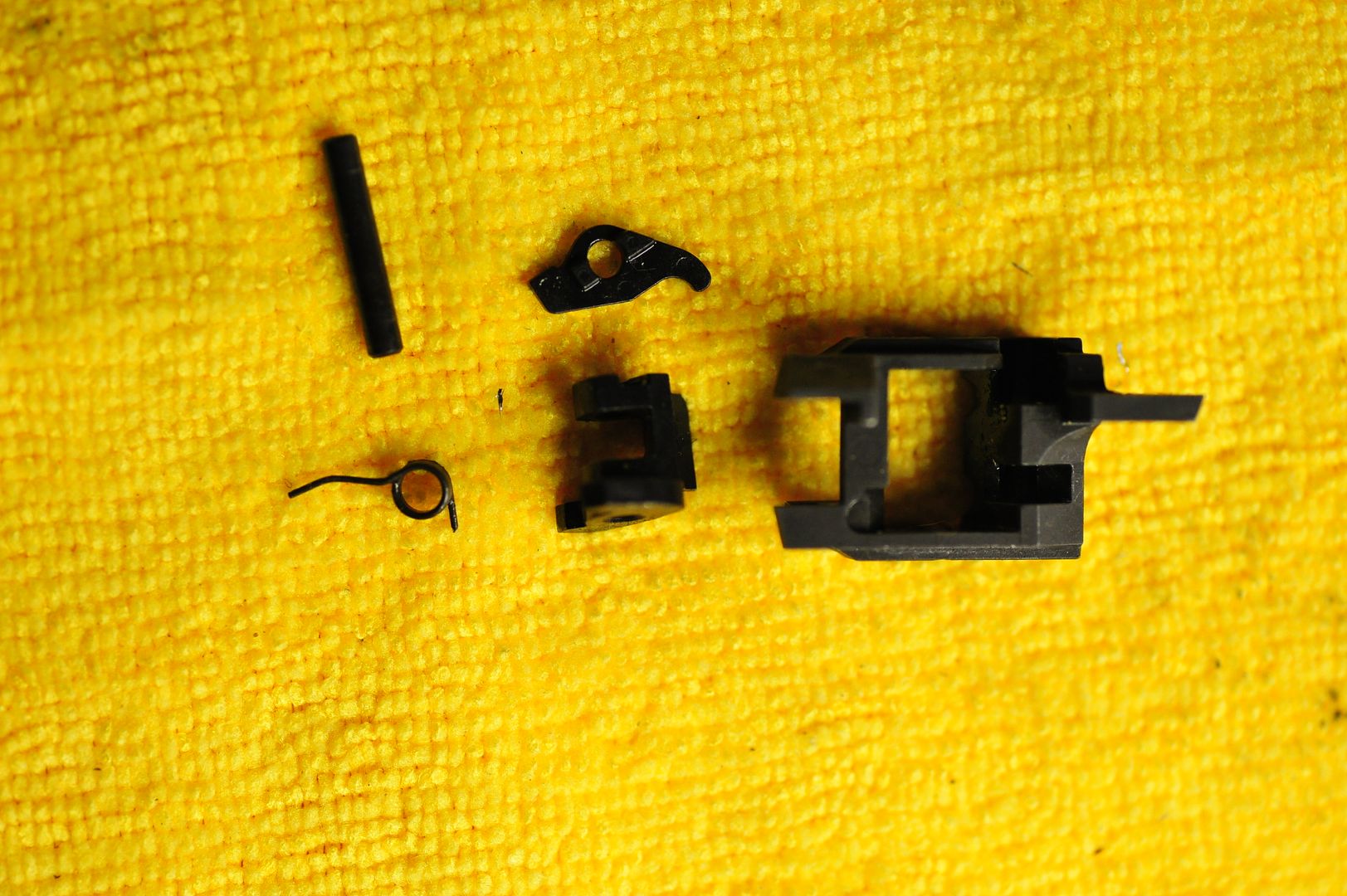

Here are the loose parts.

Someone asked me at one point can the stock sear be used with the new hammer.

Someone asked me at one point can the stock sear be used with the new hammer.

The answer is on a CZ yes, on a Canik/Tristar NO ABSOLUTELY NOT.

David, aka Schmeky made an important improvement on his hammer sear kit.He separated out the Firing pin Block lifter from the sear function, it is floating even though they are both moved by the same trigger bar.

Whys is this important??

The race hammer has a smaller shelf on the hammer for the sear.

It takes a smaller movement of the trigger than the stock hammer.

With the new sear kit the firing pin block moves sooner than the sear so that once the sear is disengages the firing pin block is already out of the way.

In this picture you can see the FPB lifter moving up and the hammer in the background is still stationary.

The Stock sear and FPB lifter are dovetailed to each other so they move at the same time and the FPB does not get the headstart it needs with the new hammer.

With the stock sear the hammer would drop before the block would move up and the gun no go BANG!

Bad thing if you are defending yourself.

So major props to CGW for doing all the development work to these guns work with a race hammer. Now to the fitting.

I wound up removing material in 2 places on the left side wall inside what I call the sear window, and to the right side of the safety arm on the new sear.

First I scribed a line of .5mm on the sear cage and used a dremel with a flat grinding bit against the surface I wanted to modify.

The scribe line allowed me to make sure the cut remained square and give me a reference for how much material I removed even though I did not go all the way to the scribe line.

I ground a little and then tried a fit and gournd some more and tried again until I felt I had it. It takes longer but it is better than cutting too much, superglue will not put it back.

Once I had that I still felt that the safety arm was rubbing too much as in it touched period.

So I removed some material off the inside of the arm.

So now I have all the parts the way I want with one exception. I like to polish the sear pin.

I know I said I would do all the polishing later, but I would rather not tar down the sear cage again when I do the other parts so I am going to cheat tonight on this part.

I chuck it up in a drill sand the pin with 800, 1000, and 2000 grit sandpaper to get a mirror finish. Then I turn it around and do the other side.

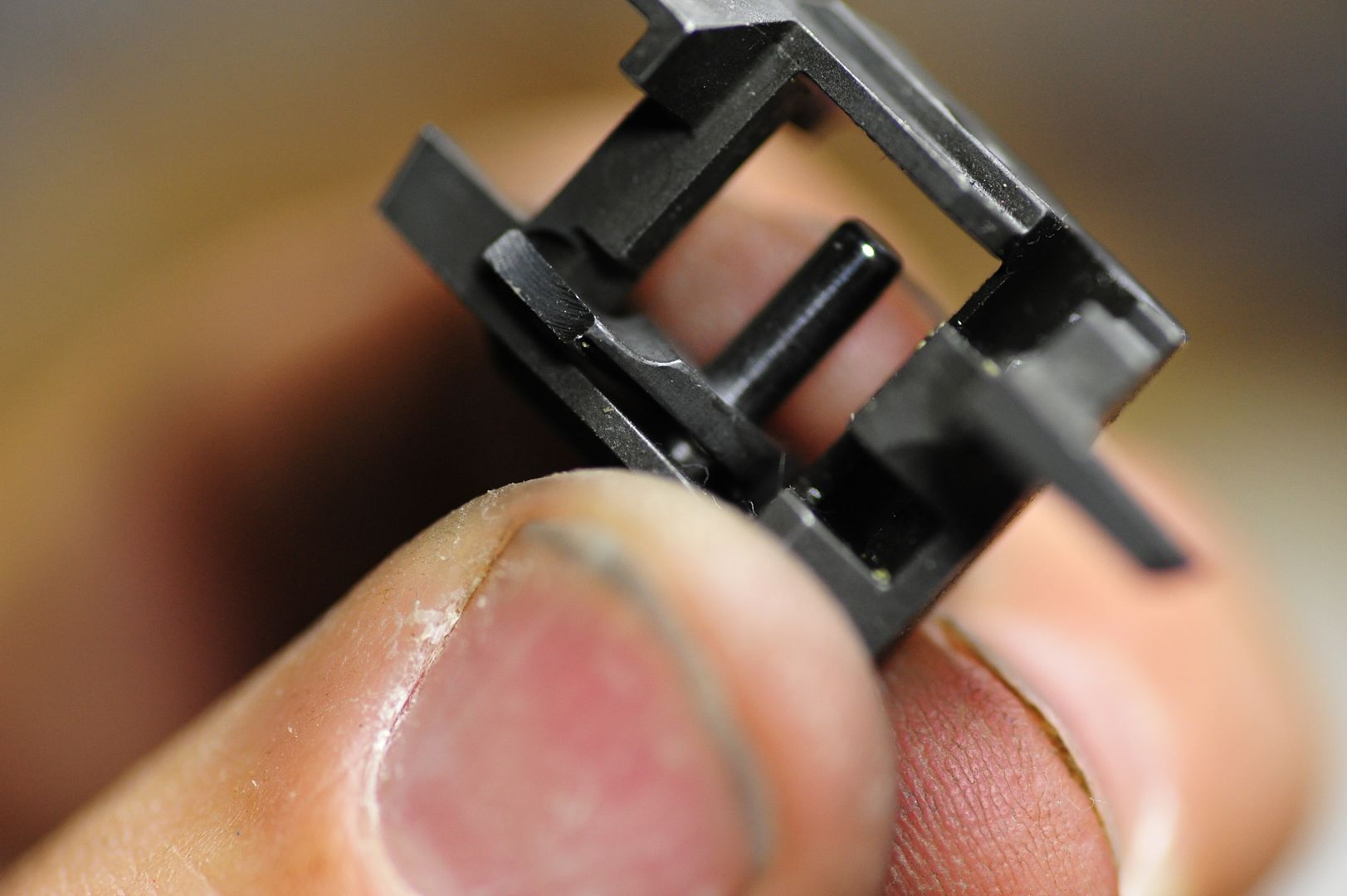

Reassembling the sear,

I tend to start from the FPB lifter side, I put the pin in a small amount and slip the FPB lifter spring on it. that is the first thing on that side, make sure the V shape is facing up.

Next I install the FPB lifter and set the spring in the grove on it.

Then I install the sear pushing the pin in just far enough to hold it in place but not interfere with the sear spring.

I put the sear spring in the middle of the sear, again make sure the V is facing up and that the top leg is resting on the back of the sear.

I will use a Drift punch to press the spring back while I push the pin through the hole. Like this.

Now you finish pushing the pin the rest of the way through the sear cage and you have completed all the hard work.

Some guys do it the other way and I have tried it both ways, I like this way as I loose fewer of the FPB lifter springs, OH YEAH order extras of those, they fly away regularly.

Once the sear is assembled make sure you have no binding and the safety arm should be lifted UP by the spring.

The FPB lifter should be pulled down by the spring. Check them I hook a finger nail under the FPB lifter and pull it up and see if it snaps back it should move freely. Same thing with the sear, press down on the safety arm and see if it pushed back easily on its own. If not on either one you may need to trim some more.

reinstall the sear into the body of the gun, They slot in real nice on tight on the Caniks this is something that I think that they are tighter than a CZ on.

lift your sear spring up like when you removed your safety rest it up high. reinstall your safety.

Tip here, before you loose your ballbearing put a little dab of grease behind the ballbearing it will help hold it in while you are installing the safety.

Slide the sear spring back onto the safety locking it in place.

REinstall the hammer spring and retainer.

Here is something that I like about all CGW sears over CZC I really like the adjustable sear, it saves a lot of time.

to set the safety, cock the hammer fully, engage safety (if safety will not engage then loosen the allen screw until it will)

once safety is on with the hammer back tighten the adjustment screw until it is against the safety.

Try disengaging safety, if it disengages, then pull the trigger if the hammer drops good.

Pull the hammer back, try reengaging the safety if it engages pull the trigger you should not be able to drop the hammer.

Do this back and forth a few times and feel the engagement of the safety will it click on and off with your thumb?

Does it lock the hammer back, does the hammer fall everytime when the safety is off and the trigger is pulled.

If so you have found the engagement point. Back it out and apply the locktite that Schmeky recommends and go back to your set point, you should have a good feel for what it feels like after fine tuning it in advance.

Well this segment was a lot of work with the trimming needed.

Once I finished reinstalling the slide there was one more function check to do.

Just as CGW tells you, you will need to check to make sure the firing pin block lifter is working correctly.

This is easy, put he gun in your right hand, cock the hammer, now pull the trigger while holding the hammer.

While the trigger is pulled, take a drift punch and push forward on the firing pin. It should push forward until slightly recessed in its hole.

If it does, then release the trigger and try again, now it should not move forward into the hole.

This is all in the instructions and it is very important! Again if it does not work the gun no go BANG!

Well was it all worth it.

Absolutely, I like a smooth trigger and this one keeps improving with each stage.

Now for some measurements.

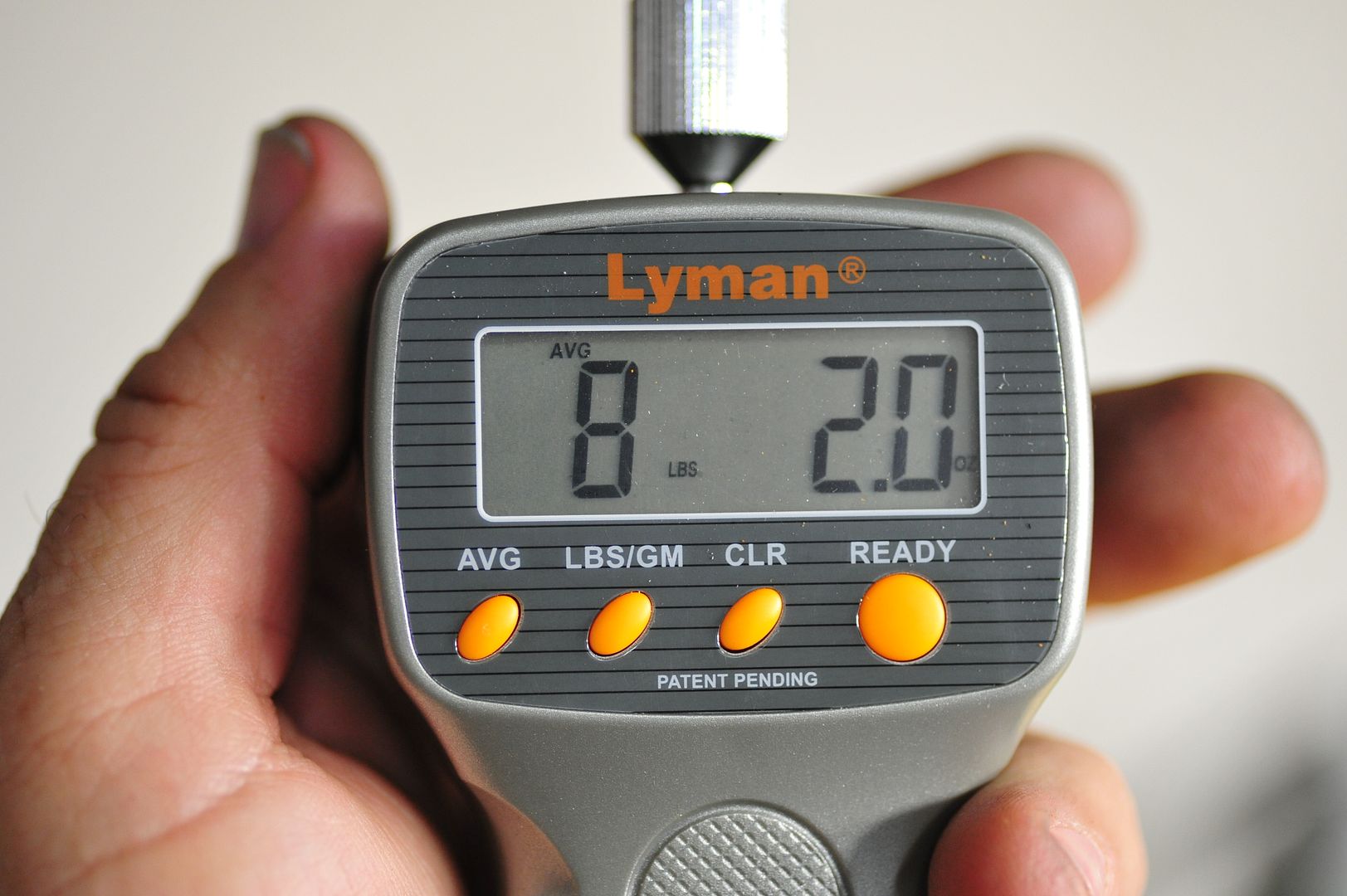

DOUBLE ACTION 8LBS. 2 0Z. that is an improvement of 4 oz. on the DA. over just the springs. Not that much but this modification is more about the SA pull both in weight and in feel.

SINGLE ACTION 3 lbs. 9.7 oz.

That is 14.1 oz. lighter than the springs alone! big jump and now we are a combined 1 lb. 6.3 oz lighter than stock!

Here is the kicker, this is as much about the short trigger pull from the SA from engagement of the sear to the drop of the hammer. That movement is less than half the distance it was previously. I am sorry I did not measure before but believe me that this trigger is nice and short and crisp!