Toby -

Not to worry. These are all issues that every reloading competitor has to go through. I went through many of the same experiences. Here are some helpful hints...

First lesson: When making any changes to loads make sure you test them before using them in competition.

Second lesson: The Factory Crimp die and Taper Crimp die are different tools and their output isn't the same.

Third Lesson: A flat anvil works best with the flat nose on SWC bullets.

?

Excellent !! You're on your way. To that I would add one more... Use a cartridge gauge on every competition round before putting them in the plastic box. Rounds that have passed the gauge "plunk test" get a red check mark at my house. This distinguishes them from plinking or simple test rounds.

Les dimensions de la cartouche SAMMI

Les dimensions de la cartouche SAMMIWith the taper crimp die I was crimping down to 0.472 only.

? The 0.473" mouth dimension given in the reloading book diagram is the

Maximum allowable. You need to be .002-.003 smaller than that number in order for

every bullet to "fall" into the chamber. Using a cartridge gauge will prove that to you.

Finding this round just cut my stage time by 10 seconds... and I've not even left the house

Finding this round just cut my stage time by 10 seconds... and I've not even left the houseI was under the impression that you needed to crimp enough to remove the bell but not enough to leave a mark in the bullet. This will not be possible with the 0.452 SWC lead bullets.

? You've confused the "expected result" with the "No. 1 rule". Use your Lee

Taper Crimp Die to get the cartridge mouth down to 0.470 inches. THEN, the indent on the bullet should be insignificant. But by staying away from the Lee

FCD, at least you won't be re-sizing the whole bullet. If there happens to be a mark on the bullet, then at least it will be minimal and localized, and therefore not likely to affect your bullet-to-barrel fit, thus accuracy.

If you'll go back in the threads in which this statement was originally made, you'll see that this observation was made in reference to

plated bullets, of which it is extremely important NOT to break through the copper cladding. Plated bullets would be .002" smaller than the lead examples you're using. In fact, your lead bullet may end up with a ring, but it is of small import when compared to

chambering the round. Consider.... if you

can't chamber the round, then the presence of a ring on the inside of the case is of VERY small import.

Does anyone have experience using SWC's in 97BD?

? The dimensions for SWC in 1911 have been cast in stone for 100 years. Since the 1911 is fairly picky about OAL, just a hunch would tell me to start with the same exact OAL and load data already in your manual. Generally SWC rounds have the shoulder of the bullet above the case mouth by ~.030-.035 inches.

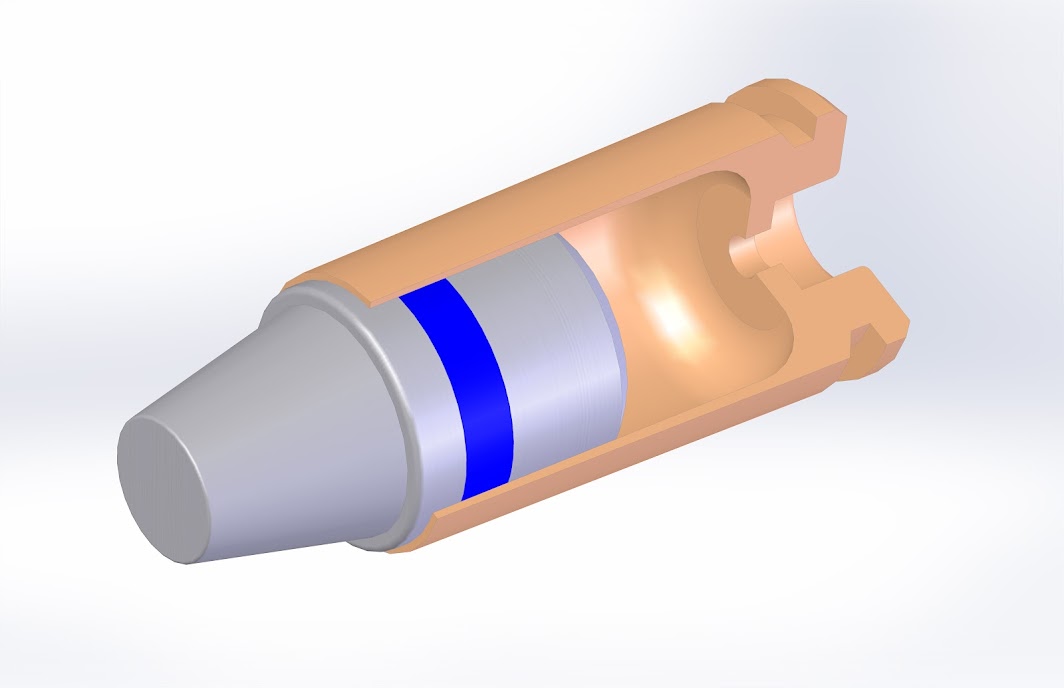

This is a depiction of SWC in 9mm, but the rules are the same

This is a depiction of SWC in 9mm, but the rules are the sameI pulled the remaining bullets out and reseated them to 1.26 inches

? In cartridges with no roll crimp, you may simply run them back through the press to achieve a shorter OAL. Disassembling ammo represents a lot of hard work to no real advantage. And certainly, there's no need to pull out the

FCD just to get the correct crimp diameter. Not to discourage in any way, but IMHO you are now 'backing up'. In

Star Trek parlance, "This does not compute." Que the 'moanback' soundtrack.

Hope this helps, because you have the right equipment and technique, and are

very close to making perfect competition ammo. Hopefully this info just might put you '

over the top' on these last few issues. At least that's my sincere intent.